The process of creating a complete virtual model of a system or robot by simulating components and control programs can impact the efficiency of the whole project. The level of details and accuracy of the simulation environment areas can be analyzed which can affect the development life circle of the robot to an extent and it also affects cost. Robotic software simulators are used to create an application for the robots physical structure without depending on its actual machine which goes a long way in saving not just the cost but also time. With the Evolution of simulation software’s, new features that make simulation a lot easier has been added making it very close to being real.

Most simulation tools can function with programming languages like C/C++, Python, Java URBI or MATLAB however, because of their purpose or area of specialty, they offer broadly varied features.

Benefits of robotic simulators:

- Reduction of the production cost of the robot

- The diagnostics of source codes that control a particular resource or a combination of resources.

- It makes it possible for different alternatives to be simulated without having to involve the physical cost.

- The different parts of the robot or its components can be tested before they are implemented.

- Robotic simulation can be carried out in stages which is a great advantage for complex projects

- Simulations can be used to test the viability of the system

- The compatibility or the system can be tested with a wide range of other programming languages

- It saves time.

Disadvantages of robot simulation software:

- When using a simulator, it simulates only what it has been programmed to simulate, it would not be able to simulated internal or external factors that weren’t looked into at the development stage.

- All the possible scenarios a robot may encounter in the real world cannot be simulated, so simulations do not offer complete data.

There are different types of simulation based on the programming language that is compatible with the simulator. Take a look at the type of simulation that best suits your requirements:

- Virtual robotic toolkit: This simulator is from Cogmation Robotics, and it is compactable with programming languages such as LEGOMndstorms or VEX depending on the version you use.

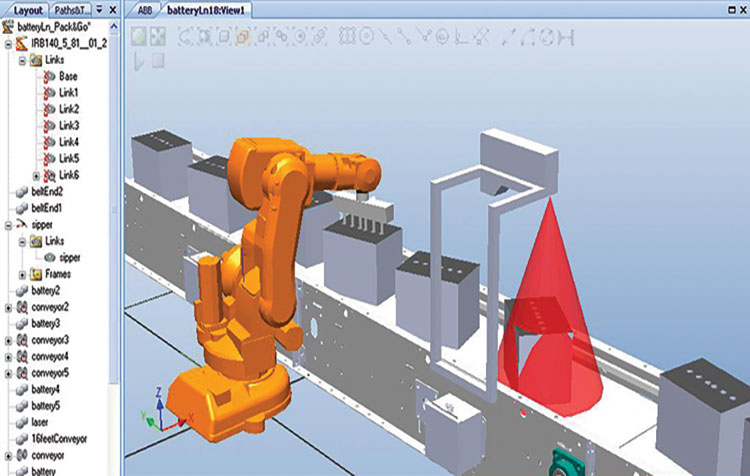

- Visual components: This is an advanced design and simulation suite for the production line. It can simulate a complete manufacturing process and would include analysis, robotic assistance, material flow, and other factors.

- RoboDK: This is an offline programming tool that allows scripting using Python or creating programs visually using its integrated 3D simulation environment.

- Microsoft robotic developer studio: This creates a 3D simulation of your robot and environment. It is compactable with LEGOMindstroms, VEX and others.

- V-REP: This 3D simulator is compactable with Windows, Mac, and

There are many more types of simulator, so the only task is finding the simulator that gives the information you want.

Refrences:

https://smashigrobotics.com/most-advanced-and-used-robotics-simulation-software/

https://en.m.wikipedia.org/wiki/Robotics_simulator